SALIENT FEATURES:-

- Pulleys are dimensioned, designed and constructed according to characteristic of each belt conveyor system of ATC. Pulleys are manufactured using material of the highest quality, strict process control and employing advanced technology. Dependable, long performance, rigid sturdy design and reduced maintenance cost

- Apt selection of pipe shell, side and stiffener plates, welding method, type of fitment and shaft design.

Sizes: 200-1200mm dia x 500 – 2500mm length

- Types: Head, Tail, Snub, Bend, Take-ups, Wing pulleys. Also motorized with a built-in drive and transmission

- Smooth steel surface without lagging for small belt width and power, dry and non-drive ends application

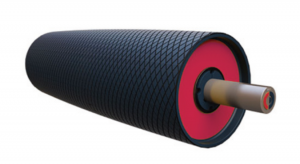

- Herringbone rubber lagging has big frictional factor, better anti-slipperyand drainage ability, but has its own direction. Diamond-rhombic laggings are good with better grip for two-way operating conveyors

- Hot vulcanized / cold adhesive bonding

- Bearings: S K F / FAG / RHP / Asahi / NTN / NSK etc. Plummer block spherical roller – pillow block ball bearing

- Wide range of light, medium and heavy duty pulleys

* Material Shell is Carbon Steel ASTM 106 grade B; CS 235-275 JR or equivalent; S haft: C45 / EN08; EN19

* Types of fitment – Shrink fit (shaft-bush); bush-key type, removal shaft type. Drums with flanged bearing and fixed shaft, locking assembly: ring feeder, taper lock bush etc

* Wear resistant rubber laggings.

*Rubber surfaces-flat, rough top, herringbone, diamond / rhombic patterns; crowning.

* Surface treatments: spray paint enamel- epoxy PU; Galvanized, rubberized, stress relieving, static balancing.

* Suitable for continuous / intermittent operation in extremely hot and humid or wetand cold environment.

*Work carried out at the factory as well as at customer plant site, in accordance with international standards and procedures.

* Applications: crushers, cements, iron, aluminum, coal, power, port and warehouse handling systems.

Rubber Lagged Drums and Pulleys

Size range: For Belt Width 500mm to 1600mm

Application: Drives the whole conveyor system

Drums: ATC offers Drums and Drum related components that are designed specifically

to meet the needs of the customer. Drums are classified as :-

- Head Drum or Driver Drum that drives the whole conveyer system.

- Tails Drum that assists in returning the belt conveyer to the Driver.

Drum Lagging: Rubber lagging of the conveyor drive pulleys considerably improves the service life of conveyor belt by resisting moisture and dirt buildup on them which results in irreparable damage by miss-tracking. Lagging process is carried out by chemically bonding abrasion resistant lagging material to drive pulleys substrate after surface preparation; which increases the coefficient of friction between pulleys and conveyor belts. Groove lagging dissipates any film of moisture in humid operating conditions. Vulcabond lagging resists abrasion and reduces noise in all cases.