ARIANE conveyor rollers are designed for medium to heavy duty requirements for bulk material handling operations in various industries such as cement, stone crushing and Screening, steel, batching, asphalt and block, construction, fertilizers, warehouse, packaging and similar industries.

ARIANE rollers are suitable for continuous operation in the extreme weather conditions such as wet, cold, hot and humid environments.

ARIANE Conveyor Rollers are designed for endurance. The components originate from quality sources. Balancing is ensured by using concentric pipes, precision end – caps and double – bored spindles. ARIANE rollers have low frictional resistance and are lubricated for life and Double Sealed to resist dust penetration.

Size range : For Belt Width 500mm to 1600mm

Application: For easy and smooth conveyor movement

SALIENT FEATURES:-

* Rugged construction, Premium design for bulk material handling application

* Precision manufacturing ensuring strict tolerances and fitting

* Lubricated and sealed for life – maintenance free

* Low eccentricity and balancing for smooth running

* Low noise, starting and frictional resistance for better efficiency and power cost savings

* Wide range of working temperatures from 0º C to 70º C

* International specification and customized Indian needs and requirements

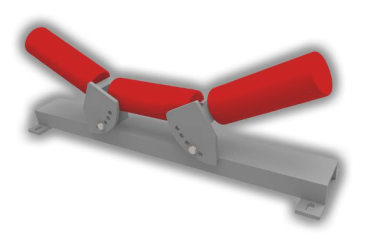

MONOTROUGH CARRIER ROLLER

The monotrough idler set consists of three equal – sized Carrier rollers slotted or grooved ends. I n this arrangement the side rollers can be set at any pre – determined angles of

25º, 30º, 35º or 45º.

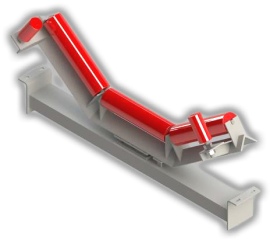

VARIATROUGH CARRIER ROLLER

Variatrough Idler set consists of two types :

A – side rollers.

B – entre rollers.

Side rollers of this arrangement can be set at angles of 20º, 30°, 40º, 50º or 60º in order to achieve the desired belt trough.

Tube Diameters 60 to 159mm, shaft dia 20 to 50mm; for belt widths 400mm to 2400mm

SELF - ALIGHING CARRIER IDLERS TRANSOM SETS

Sometimes difficult working conditions result in lateral movement of belts. Usage of self – align carrying idler transoms set help to correct belt tracking and maintain its centering. The Idlers are mounted on centrally pivoted stationary frame to swelling ring/bearing which permits rotation (5º to 10º). Vertical guide roller is provided at each end of swiveling frame which tries to push the misaligned belt towards conveyor centre line. These rollers can be aptly positioned at 15 to 20mtrs from end pulleys at pitch of 30 to 40mtrs on long conveyors.

SELF ALIGHNING RETURN IDLERS SET

Self-aligning return idlers under the return belt run at an interval of 21 to 30m in place of usual return idler. General practice is to use such idlers at every 7th to 10th pitch of standard Idler. The idler applies aligning force on return belt run whenever it deviates from conveyor centre line.

V-TYPE RETURN IDLER SET

The idler set consists of a pair of rolls or mounted on a steel frame. The troughing

angle is generally 10º but 15º is also used. The belt is in trough form and

therefore it has advantages of self-aligning – autocentering actions attributed

to trough space.

ARIANE IMPACT ROLLERS

Feed rollers are covered with specially – designed rubber rings of adequate thickness and resistance. Impact rollers are positioned in cases where sharp – edged and pointed material is continuously falling with great force. Conveyor belts are subjected to a particularly high level of impact strain and subjected to damage at their feeding points. In such cases the conveyor belt is subjected to the risk of penetration and ply injury. Specially – designed closely – spaced impact rollers are used on the carrying side of the mono trough transoms to soften the force of impact and absorb shock pressures.

ARIANE SUPPORT ROLLERS

Support rings make it easier to keep conveyors clean, prevent material clogging on return idlers and promote tracking. Steel rollers made of concentric tubes are generally used in mono trough transoms as return rollers. However in applications where the return side cannot be turned over or when the material conveyed is sticky, specially – designed support rings are fitted on the return roller.

The use of support rings substantially reduce the cost of cleaning maintenance, prevent material caking on the return rollers, promote smooth straight tracking of the belt and reduce breakaway resistance on start-up. ARIANE SUPPORT RINGS make it easier to keep a conveyor system clean. They have proven particularly successful on systems where the return side cannot be turned over. When support rings are drawn over the existing idlers in accordance with assembly instructions, the small contact area of each ring leaves merely a thin trace of fine parallel lines on the belt cover.

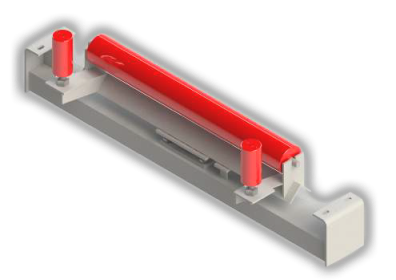

ARIANE FLAT AND RUBBER RING RETURN ROLLERS

The flat return idler has a single roll to support the return run of the belt conveyor. The idler consists of single roll and a pair of brackets to install below conveyor stringers.

- Used to sustain and support the belt during its return

- Avoids return wear, tracking issue or conveyed material sticking and carry over

- Reduces contact with surface and wear of rollers

- Helical rubber rings further facilitate aggressive cleaning, reduced material depositing on belt and roller helps tracking

- Various arrangements possible suiting applications with range of conical support and flat rings

ARIANE FLAT BELT TRACKING AND SELF CLEANING ROLLERS

Spiral metal coil turns running from center left and rightwards provide belt cleaning during its return, reduce material depositing and facilitate tracking.

Also available in hollow tube spiral coil construction

GARLAND – SUSPENDED TYPE ROLLERS

This type of idler has 3 or 5 rolls of equal or unequal lengths which are linked in series and suspended at the ends by special lugs to the conveyor – stringers, to form a continuous chain of idlers. Garland Idlers have a link assembly between the connected rollers.

Characteristics

1) Garland Idlers are lighter when compared to fix – frame idlers due to the absence of a steel frame.

2) Garland idler design is more forgiving than fixed, due to its chain – like design which allow the belt’s center line and idler centers to move relative to the supporting frame.

3) Finds application more on yard, dump and shift able conveyors, where alignment of conveyor structure may not be correct due to the mobility of the conveyor on ground conditions.

ARIANE GUIDE ROLLERS

Guide rollers are mounted vertically or at a suitable degree on transoms to restrain a belt ‘s lateral drift or movement. Most apt location of mounting is on a self-aligning transom. Rollers with one side shaft and threaded ends are most common.

ARIANE INDUSTRIAL ROLLERS

We produce a wide range of industrial rollers including V-rollers, nip rollers, idler rollers, feed rollers, pulleys, drive wheels, ringer rollers, polyurethane rollers and custom-shaped rollers.

ATC’s in-house machine provides the ability to fabricate new rollers or wheels, as well as refurbish and recover existing rollers. Our precision machining ensures required dimensional tolerances and surface finish.

ARIANE ARMORED ROLLERS

Armored is a range of products developed by ATC to suit extreme conditions. Applications range from military, desalination, road and transport and bulk material handling.

The Armored roller is a first of its kind, designed for five years of operational life. Its rugged design ensures sustainable uninterrupted operation.

It is also lighter than the average idler, ensuring low power consumption of the conveyor and easy maintenance. Special bearings ensure low roll resistance, further reducing power requirements during start/stop operations.

The Armored layer ensures low abrasion, belt friendly operation, high resistance to chemical agents, corrosion resistance and low noise operation.

The layer is also self cleaning, preventing material build-up limiting belt misalignment issues.

Armored rollers can be made up to 2000mm width, allowing it to be used as a return roller. The rollers can be customized to the customer ‘s requirement.